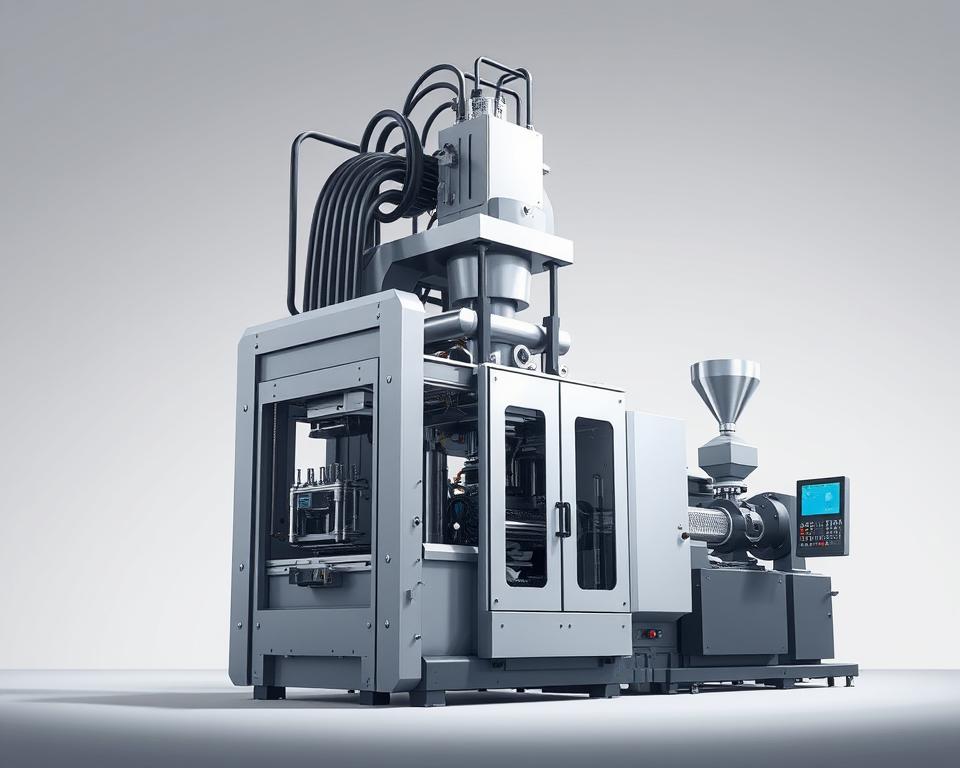

Step‑by‑Step Guide to Sourcing Injection Molding in China

Well, the major meeting has just concluded. your new product has been approved, the schedule is tight, and the budget is, let’s say, constrained.. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Naturally, you agree. It makes sense on paper. The potential savings can be massive. Yet your thoughts are already spinning. You’ve heard the stories, haven’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It feels like walking a thin line between big savings and total project failure.

But here’s the catch. Sourcing plastic mold doesn’t have to be a gamble. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Disregard those scary tales. Here’s a practical playbook to nail it.

Step One: Do Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You cannot expect overseas partners to interpret your unspoken requirements. It’s akin to asking someone to price-build “a structure” with no details. You’ll get wildly varied quotes that are useless.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. It’s the cornerstone of your entire effort.

What belongs in your RFQ?

Begin with 3D CAD models. These are non-negotiable. Use standard formats such as STEP or IGS to ensure compatibility. This is the master blueprint for your part’s geometry.

However, 3D alone won’t cut it. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Any seal surfaces or critical hole sizes must be clearly labeled.

Then specify the material. Don’t just say “Plastic.” Nor just “ABS.” Be specific. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. Why so detailed? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with what is plastic mold.

Your supplier might propose substitutes, but you must set the baseline.

Don’t forget the commercial info. What is your Estimated Annual Usage (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

Finding the Right Supplier

Okay, your RFQ package is a work of art. who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. But think of them as a starting point, not the finish line. Narrow your pool to about a dozen promising firms.

Still, you must dig deeper. Think about engaging a sourcing agent. They do cost extra. But a reputable agent brings pre-screened factories. They are your person on the ground, navigating the language and cultural barriers. For a first-time project, this can be an invaluable safety net. It’s schedule protection.

Also consider trade fairs. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Meeting onsite is unbeatable. Inspect prototypes, interview engineers, and sense their capabilities. Also, leverage the tried-and-true referral network. Tap your professional contacts. Peer endorsements carry huge weight.

Sorting the Contenders from the Pretenders

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. bids begin to arrive. You’ll see ridiculously low offers and steep quotes. Your job now is to vet these companies and narrow it down to two or three serious contenders.

What’s the method? It’s a bit of an art and a science.

Step one: audit communication. Is their turnaround swift and concise? Is their English good enough for complex technical discussions? But the key: do they probe your RFQ? The best firms will question and suggest. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” That’s a huge positive sign. It shows they’re engaged and experienced. A supplier who just says “No problem” to everything is a walking red flag.

Next, dig into their technical capabilities. Ask for a list of their equipment. Review examples of parts akin to your design. Don’t pick a micro-molding shop for large components.

Next up: the factory audit. You can’t skip this. As you vet staff, you must vet suppliers. You can travel or outsource a local inspector. They dispatch an on-site auditor for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s the best few hundred dollars you will ever spend on your project.

From Digital File to Physical Part

Once you’ve chosen your supplier. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Now the process kicks off.

Initially, expect a DFM report. DFM means Design for Manufacturability. It’s the engineering critique for moldability. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. A detailed DFM shows expertise. It’s a two-way partnership. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are your initial mold shots. It’s your test of success.

T1 parts usually require adjustments. It’s par for the course. You’ll find minor defects, off-spec dimensions, or finish issues. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold samples. This process might take a couple of rounds. Build buffer time for sample iterations.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is now the benchmark sample. You ratify it, and it becomes the quality yardstick for production.

Final Steps to Mass Production

Getting that golden sample feels like the end, but it isn’t. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. This often involves a pre-shipment inspection. Again, you can hire a third-party service. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They provide a photo-filled inspection report. Once you sign off, you greenlight shipping and the last payment. This simple step prevents you from receiving a container full of scrap metal.

Don’t forget shipping details. Know your shipping terms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, shifting all transport to you? These choices hugely affect landed cost.

China sourcing is a long-haul effort. It’s about building a relationship with your supplier. Treat them like a partner, not just a line item on a spreadsheet. Transparent dialogue, respect, and process discipline win. Certainly, it’s complex. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re set to succeed.